Currently supplying Conventional, Open Hole, Swellable and Thermal tools to Canada, Europe and South America, Boss Completions has over 20 years of experience working with downhole tools.

With varying factors like the geological conditions, well design and specific objectives of the drilling operation, Boss Completions has the tools required in achieving successful drilling outcome.

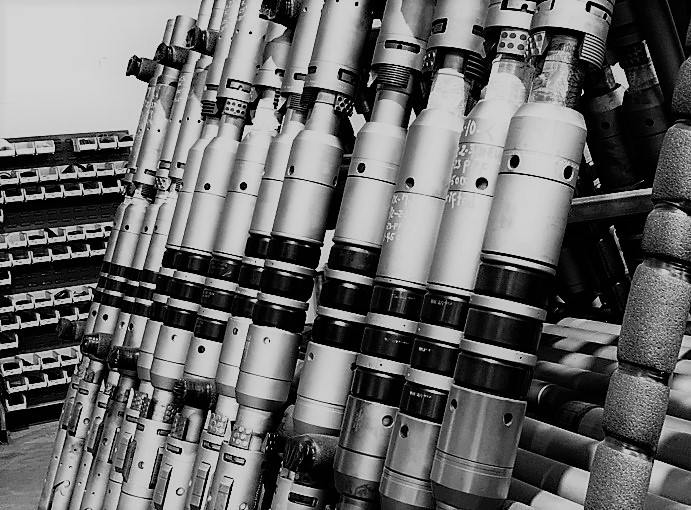

We pride ourselves on having an extensive catalog selection of conventional down hole tools. From Bridge Plugs, ECP’s to Liner Top Packers we support both drilling and completion operations. With our vast knowledge of the downhole use of our products we can supply our customers with exceptional products tailored to their needs.

Perforating guns are specialized tools used in the oil and gas industry to create openings or perforations in the casing, cement, and surrounding rock formations of a wellbore. These perforations allow the flow of hydrocarbons (such as oil and gas) from the reservoir into the wellbore, enabling production.

The perforating gun is typically loaded with shaped charges, which are explosive devices designed to create precise perforations. When detonated, these charges generate high-pressure jets that penetrate the wellbore wall and surrounding formations.

Perforating guns play a crucial role in the completion phase of a well. They are carefully positioned and fired to ensure that the perforations are strategically placed in zones of interest, allowing for efficient extraction of hydrocarbons. This process is vital for maximizing well productivity.

We are the EXCLUSIVE distributor of Harrison Jet Guns perforating guns and charges in Canada.

Swell packers, also known as swellable packers, are specialized downhole tools used in the oil and gas industry for wellbore isolation and zonal control. They are designed to expand or “swell” when in contact with certain well fluids, creating a seal or barrier within the wellbore.

Swell packers are typically composed of elastomeric materials that have the property of absorbing fluids, causing them to increase in size. When deployed downhole, swellable packers are set in a specific location within the well. Once exposed to well fluids, they absorb the fluid, expand, and form a tight seal against the wellbore walls. This creates an isolation barrier that prevents the movement of fluids between different zones in the well.

These packers are crucial in various well operations, including zonal isolation for production or injection, selective stimulation treatments, and other downhole applications where precise fluid control is necessary. They are valued for their reliability and effectiveness in providing zonal isolation without the need for mechanical intervention after deployment. Swell packers are particularly useful in situations where conventional mechanical packers may not be as suitable or effective.

Thermal downhole tools are specialized instruments designed for use in oil and gas wells to perform operations that involve the application or measurement of temperature. These tools play a crucial role in various downhole processes and operations.

Thermal downhole tools are integral in optimizing well performance, ensuring efficient production, and implementing enhanced oil recovery techniques. They are designed to withstand high-temperature and high-pressure environments characteristic of downhole conditions in oil and gas wells.

Open hole tools are designed to work directly in the natural geological formations, referred to as ‘open hole’ sections of down hole drilling. These tools serve various purposes, including but not limited to logging and evaluating the properties of the rock formations, taking measurements of formation properties like resistivity and porosity and sometimes performing operations like setting packers or isolating certain sections of the wellbore.

The Boss R.I.T.T.S. is a system designed for treating, testing, or injecting of single or multiple intervals in a well-bore without the requirement for tripping between operations. The ‘re-settable’ aspect implies that it can be reused after each operation, which can be a significant advantage in terms of cost and efficiency.